ISO 9001 Readiness Checklist

ISO 9001 Readiness Checklist

You can use this checklist as an indicator of the readiness of your system for meeting the requirements of ISO 9001:2008. However, you should not rely on it entirely. It is a starting point only. You need to have a good understanding of ISO 9001:2008 in order to interpret its requirements. If in doubt, check with an expert.

You are welcome to make copies of this page and use it within your own organisation. But, please note that it is copyright of Russell, and you must not try to claim it as your own work. You must display "© Russell" on all copies - Thank you.

Have you completed these tasks?

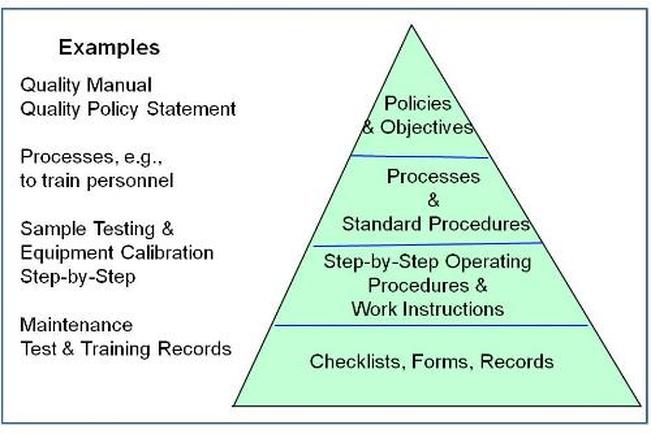

A. Documentation & Top Management Responsibilities

- a description of the scope of the system (and any exclusions, with justifications)?

- a description (or flowchart, etc) which explains how the processes interact?

- (or refer to) all six mandatory procedures:

(1) - Control of documents (Clause 4.2.3)

(2) - Control of records (Clause 4.2.4)

(3) - Control of Internal Auditing (Clause 8.2.2)

(4) - Control of Nonconforming Product (Clause 8.3)

(5) - Corrective actions (Clause 8.5.2)

(6) - Preventive actions (Clause 8.5.3)

- are they measurable?

- are they quality related? (i.e. something that affects how well your services/products meet requirements)

B. Resources

C. Production of goods & services

D. Improvements

You can use this checklist as an indicator of the readiness of your system for meeting the requirements of ISO 9001:2008. However, you should not rely on it entirely. It is a starting point only. You need to have a good understanding of ISO 9001:2008 in order to interpret its requirements. If in doubt, check with an expert.

You are welcome to make copies of this page and use it within your own organisation. But, please note that it is copyright of Russell, and you must not try to claim it as your own work. You must display "© Russell" on all copies - Thank you.

Have you completed these tasks?

A. Documentation & Top Management Responsibilities

- Produced a Quality Manual, which meets the requirements of Clause 4.2.2?

- a description of the scope of the system (and any exclusions, with justifications)?

- a description (or flowchart, etc) which explains how the processes interact?

- (or refer to) all six mandatory procedures:

(1) - Control of documents (Clause 4.2.3)

(2) - Control of records (Clause 4.2.4)

(3) - Control of Internal Auditing (Clause 8.2.2)

(4) - Control of Nonconforming Product (Clause 8.3)

(5) - Corrective actions (Clause 8.5.2)

(6) - Preventive actions (Clause 8.5.3)

- Produced your Quality Policy? (Clause 5.3)

- Established measurable objectives? (Clause 5.4.1)

- are they measurable?

- are they quality related? (i.e. something that affects how well your services/products meet requirements)

- Defined the roles and responsibilities of your staff? (Clause 5.5.1)

- Identified the Management Representative and defined the responsibilities? (Clause 5.5.2)

- Held Management reviews of the system (Clause 5.6), and kept records of the reviews? (Clause 4.2)

B. Resources

- Considered what resources (people, equipment, processes, etc) are required to correctly supply your services or products? (clauses 6.1, 6.2, 6.3, & 6.4)

- Made sure that you supply them (clauses 6.1, 6.2, 6.3, & 6.4) and keep reviewing them? (clause 5.6)

- Conducted training as appropriate, and considered if it was effective? (Clause 6.2)

- Kept records of the training? (Clauses 4.2.4 & 6.2)

C. Production of goods & services

- Defined the processes involved in the production of your goods/services? (Clauses 7.1 and 4.1)

- Defined the processes required to support the production processes? (Clause 4.1)

- Defined the sequence of the processes? (Clauses 7.1 and 4.1)

- Produced instructions where necessary? (Clause 7.5.1)

- Made sure that your measuring equipment is working and suitable for the task? (Clause 7.6)

- Made sure that goods and components are traceable (where required) and that they are stored and handled so as to avoid damage? (Clauses 7.5.3 and 7.5.5)

D. Improvements

- Started to monitor Customer perception of your products and services? (Clause 8.2.1)

- Conducted Internal Quality Audits? (Clause 8.2.2)

- Started to monitor and measure the effectiveness of your processes? (Clause 8.2.3)

- Measured the suitability of your product/service (Clause 8.2.4) - e.g. final inspection results, etc?

- Kept records of your nonconforming product - inspection rejects, Customer returns, warranty repairs, etc? (Clause 8.3)

- Reviewed (analyzed) all of this information in order to improve the system and products? (Clauses 8.4 & 8.5)

- Taken corrective actions where appropriate, and kept records? (Clause 8.5.2)

- Considered and undertaken preventive actions, and kept records? (Clause 8.5.3)

- Reviewed all the improvement possibilities and used them for the benefit of the system, so that your products become better, you ensure that your Customers get what they wanted (and perhaps a little more!) - (No specific clause, but good business sense, and in line with the overall aim of ISO 9001:2008)